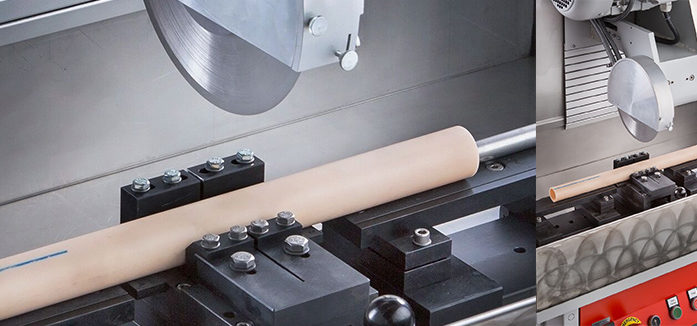

PT 378 Automatic Gantry-type Cut-off Machine

HIGHLIGHTS

- Automatic cut-off operation with variable feeds and speeds

- Operated in total immersion or with jet refrigeration = high precision, long disc life, no fine powder in the air and quick grinding

- Big range of work pieces thanks to the 3 CNC axis

- Free programming with graphical assistance

- Coolant through valves with debit control

- Work area protection with laser curtain

Useful for

- Cutting tool manufacturers and grinding services

- Tool and die as well as machine tool industries

- Material analysis

- Quality control

- Medical industry

- Compounds

- Ceramics and glass parts and many others

This gantry-type cut-off machine is ideal for rapidly cutting-off or indenting big work pieces in hard or abrasive materials. Typical applications are for instance the production of honing stones or chucks.

The modern CNC drives the 3 axis (X, Y and Z). As an option, we can add a 4th axis (divider, indexer) which gives additional possibilities. The operator-programmed CNC is simple and has a touch screen with graphical assistance.

It has drives for the axis movements, and the precision guides and roller-bearing spindles guarantee a high positioning precision. The ideal speed is set with a frequency variator. The grinding spindle with high-precision bearing gives a regular grinding.

An option allows disc wear compensation with a laser barrier. The machine stops automatically once the programmed minimum abrasive layer has been reached. All mobile machine parts have a central greasing.

The machine can be operated with cutting oil or emulsion. The coolant debit is controlled and the machine stops automatically in case of interruption. Immersion or jet coolant result in a high precision, an optimal surface condition and a long disc life.

The work piece holding will be studied and developed according to your requirements resp. the dimensions of your work piece.

For more information, please click on the respective picture.

| Axis movements | X 850 mm, Y 500 mm, Z 120 mm |

| Grinding wheels | Ø 200 mm |

| Feed | 0.01 up to about. 20 mm/s |

| Electrical power | about 10 kW |

| Dimensions L x W x H | 2450 x 1200 x 2220 mm |

| Weight | about 1400 kg |